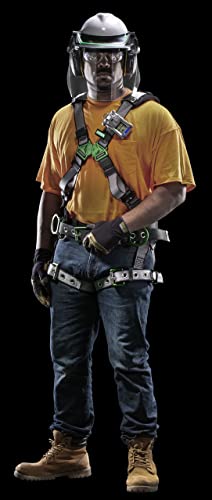

MSA Skullgard Cap Style Hard Hat - Non-Slotted, Phenolic Resin, Radiant Heat up to 350F | Fas-Trac III Suspension

Category: msa skullgard hard hat

About this item

- Sure! Here’s a reworded version of each line to avoid duplication while keeping the original meaning:

- **SPACIOUS HARD HAT:** This oversized hard hat caters to individuals who exceed the standard size range, accommodating hat sizes from 7 to 8 1/2. Typical hard hats are designed to fit the majority of users.

- **VERSATILE CAP DURABILITY:** Constructed with a phenolic outer layer and meticulously crafted for resilience, this helmet is suitable across multiple sectors. Ideal for use in steel mills, welding, construction sites, open-pit mining, oil and gas refineries, rubber production, and steam tunnels.

- **FAS-TRAC III SUSPENSION SYSTEM:** Developed with feedback from numerous users, the advanced Fas-Trac III suspension system serves as an upgraded ratchet mechanism. The rear lug attachments are flush to avoid pressure points, and the adjustable nape strap offers three settings for a personalized fit. The contoured ratchet comfort pad enhances airflow and prevents hair entanglement. With significant comfort improvements and an easy-to-grasp ratchet that rotates smoothly while maintaining a secure fit, your team will be encouraged to wear their safety helmets consistently.

- **SUPERIOR PROTECTION:** Designed for general use or in high-heat environments, these Skullgard helmets have been tested to withstand radiant heat exposure up to 350°F without exceeding that limit. A streamlined crown design allows seamless compatibility with all MSA welding gear.

- **COMPLIES WITH PROFESSIONAL REGULATIONS:** Skullgard Caps fulfill all necessary criteria for a Type I (top impact) helmet as specified in ANSI/ISEA Z89.1-2014 (Class G). These helmets have undergone thorough third-party testing and certification by SEI, meeting voluntary standards for reverse donning, low and high-temperature conditions, and high visibility. Date codes indicating the production month and year are molded into the underside of the shell’s brim, though this date does not reflect the helmet's service life, which begins upon use. – Refer to the attached FAQ sheet.